Handmade Cladding Brick

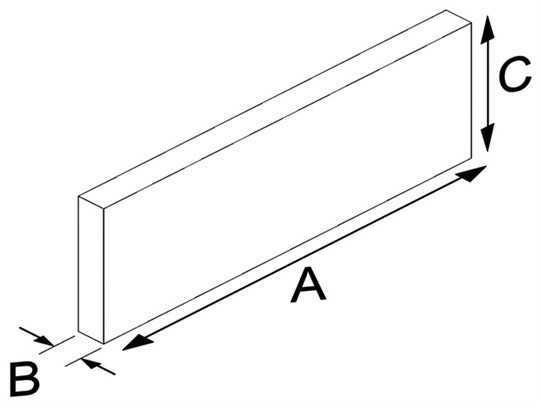

Handmade Cladding Brick| Product code | : HDK-1-GRIMIX |

| Brick Types | : Handmade Brick |

| 1-Dimensions (mm) | : A:215,B:15,C:60 |

| 2-Dimensions (mm) | : A:215,B:15,C:65 |

| Modular Dimensions (mm) | : A: 194, B: 15, C: 57 |

| Dimensions (mm) | : A:215,B:15,C:65 |

| Piece / m² | : 60 |

| Weight | : 0,39 kg |

| Active E. Salt Mic. | : S2 |

| Frost Resistance | : F2 |

| Water Absorption Rate | : Max. % 11 |

Description

Storage of Material

* Handmade bricks are presented for use in 1 m² cardboard boxes on pallets wrapped in plastic packaging.

* The pallets are loaded with the help of a forklift at the factory and are unloaded at the usage location using a forklift, crane, or by hand.

* The material inside the pallet is transported within the construction site manually by hand or with a wheelbarrow during the labor process.

* When transporting Handmade Bricks, they should be handled with care to avoid corner breakages and should be stacked properly to prevent any damage during transportation.

* Handmade bricks should be protected from rain and water in the storage area.

Tools Used in Practice

Trowel, grout float, metal corner bead, grout spacer, grout pump, spiral mixer, mortar pan, and wheelbarrow.

Surface Preparation

Handmade Cladding Brick can be applied on all rigid and stable surfaces such as reinforced concrete walls, columns, beams, hollow bricks, infill bricks, aerated concrete, rough plaster, etc. If there are any coatings or materials that may hinder adhesion, such as paint residues, insulation material residues, debris, oil, dust, poorly adhered non-load bearing plaster layers, etc., they should be removed. On larger and rougher surfaces, coatings should be scraped off, or if that is not possible, they should be re-plastered to make them smooth.

* If the wall to be applied is damp, the body and surfaces of the wall must be dried before the application.

Protection of Walls Throughout Application

Handmade Cladding Brick should be protected from outdoor weather conditions (such as rain, construction waste water, moisture, water, frost, and excessive sunlight) during the application and until the adhesive gains strength, especially in the first day after completion. For this purpose, plastic and tarpaulin covers should be placed over the application, leaving a gap between them and the Handmade Cladding Brick.

Weather Conditions, Other Considerations and Cleaning

Handmade Cladding Brick should not be applied below +4ºC.

In winter months, especially in areas exposed to freezing temperatures, the drying time of the adhesive will be longer, so the grouting process should begin 4-5 days after the application. During this time, the joint gaps will remain open, so the exposed surface of the cladding application should be protected from rain, snow, and water accumulation by using covers such as nylon or tarpaulin.

In hot weather applications, the bricks should be moistened before application as they may absorb the water of the adhesive, which will decrease the bonding strength of the bricks. (To do this, simply dip the bricks in a bucket of clean water just before use.)

During firing, tonal differences may occur in the bricks due to the structure of the soil. Therefore, to prevent these tonal differences during the application of handmade bricks, covering bricks from different packages should be obtained and blended for application.

Care should be taken not to spread the adhesive mortar and filling material on the surface of the brick during application.

When material is splashed onto the brick surface, one should wait for the splashed material to dry and then clean it with a stiff plastic brush.

Specialized Doğanay Surface Cleaner should be used for heavily soiled surfaces.

Do not apply paint, varnish, vinegar, salt water, or any similar materials to the brick surface after application.

It is recommended to work with certified professional teams for handmade brick applications.

Handmade Brick Application

* The surface is prepared according to the above principles.

* The adhesive material is prepared in accordance with the conditions of use.

* The adhesive is applied to the surface with an 8 – 10 mm notched trowel.

* Some special Doğanay Flex Brick Adhesive is applied to the back side of the handmade brick and adhered to the surface smoothly with 1 cm joint with the help of metal lath, rope, plastic joint plus or wedge.

* During the knitting process, care is taken to ensure that the horizontal and vertical joints are level and plumb.

* After the adhesive dries (24 hours), the laths should be removed and the joint filling should be started.

* The joint to be used for Handmade Bricks can be applied with a minimum width of 10 mm by choosing the special Doğanay Flex Joint Filler.

* Joint filler should be applied without contaminating the brick surface with the help of a joint gun.

* When the joint filler is dry enough not to stick to the hand, it should be shaped with the help of a joint trowel.